Hi All,

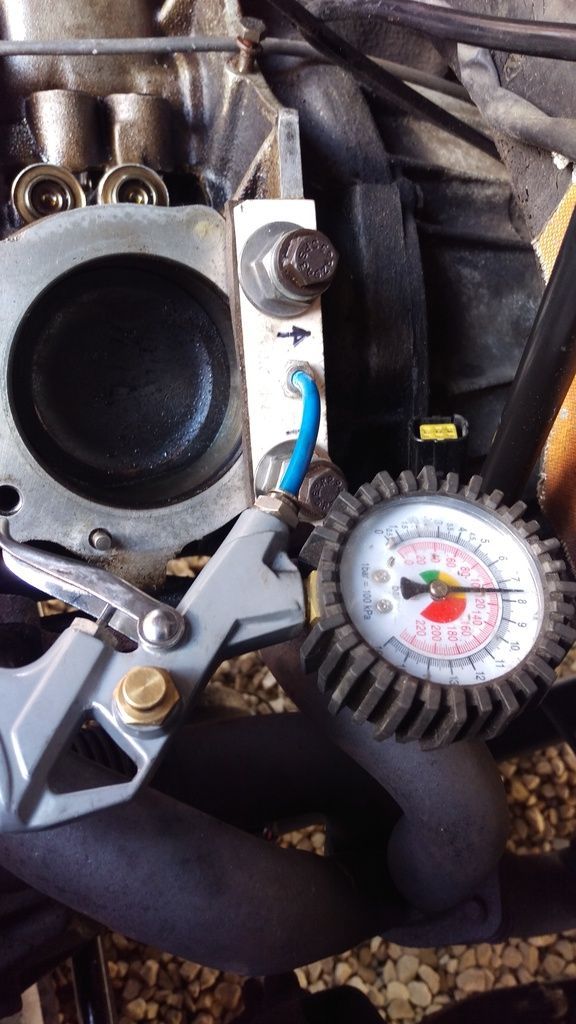

Well I've tested my block to 7.5bar 115psi and no failure? I.m unable to get to a higher pressure as my compressor will not go any higher.

only tested the side that has signs of water in the head, held pressure for 1hr and no leaks.

Will start the rebuild process with different heads.

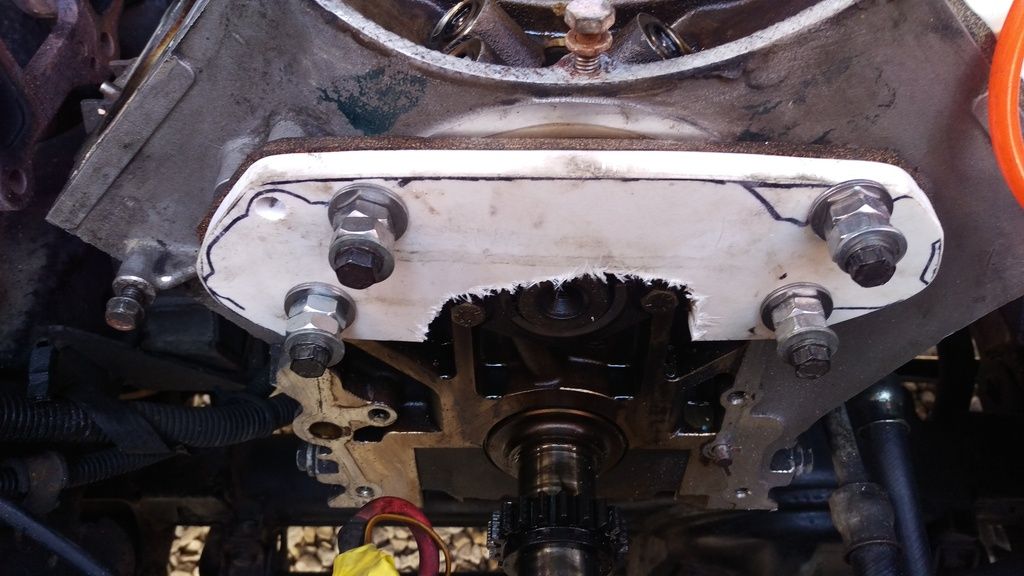

I've also made a plate for the water pump but not tested

The cap of the overflow bottle lifts at 1,5 bar from memory so your block is tight...

Yes overflow on bottle is 1.5 bar, but to get gas in the water from your liners you need to prove that it holds pressure that can be generated within the combustion chamber which is high 8 bar +.

I still have no idea what caused me to have gas in the water in the first place?????

If you're running on LPG and the diaphragm in the reducer is starting to perish, LPG can seep through into the coolant passage in the reducer. That will give a positive reading for hydrocarbons in the cooling system. It's not common but has caused quite a few people to strip their engines down unnecessarily.

Hi Gilbertd, I wish that was the case. Its a total mystery i have no idea whats caused it, on closer inspection of the head the 2 valve sets that had signs of water (pint colour valve heads (been told thats gycol burning)) both Inlet valves were not seating very good and 1 fixing pin for the air manifold on the head had a build up of that steel seal around it?

So could my fault been around this section? where the water passes the inlet manifold to the head????

If there's a build up of leak fixing gloop, then it was trying to do what it is claimed to do and plugging a gap, so that would make sense. Getting coolant into the inlet passages would allow it into the combustion chamber but whether the fuel/air mixture in the manifold would manage to go the other way, I've no idea. I would have thought it wouldn't but I suppose it depends on how sensitive the testing stuff is.

Just a few comments on pressure testing :

Firstly, I must admit I have never pressure tested an engine block but I have pressure tested lots of industrial pressure vessels and steam boilers.

Pressure testing is always done with a fluid (usually water) as it is non compressible. If there a leak, the pressure is lost immediately and can be seen right away.

Using compressed air, the pressure will not drop much through a tiny crack. It does not reveal anything unless it is a big leak.

After completely filling the vessel, we used to use a hydraulic hand pump to pump water in and get the pressure up. If you don't have one, I would have thought mains water pressure would be probably enough, it is usually 50 psi+ . Just put mains water pressure on the jacket, get all the air out, then valve it off and see if it drops, normally over a period of 2 hours.

Edit: Just read your other post and I see your engine is all back together so a bit late with this.