Whilst at Gordon's this evening, once we'd got his car running again we had a very quick look at the software for the LPG on my VSE.

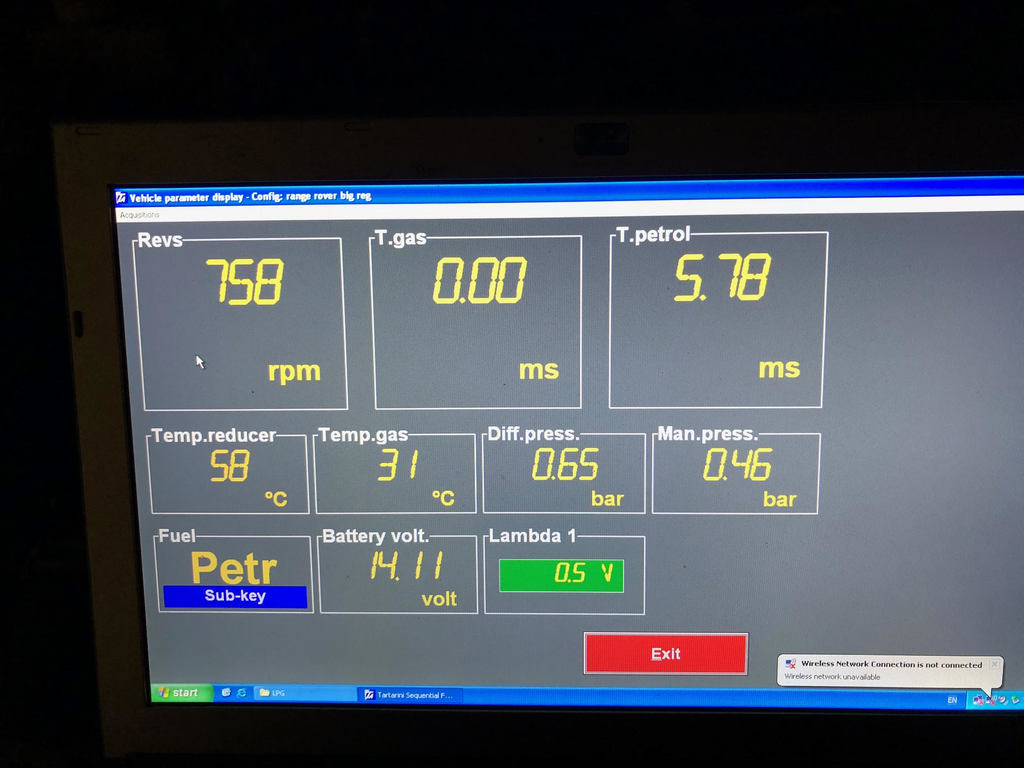

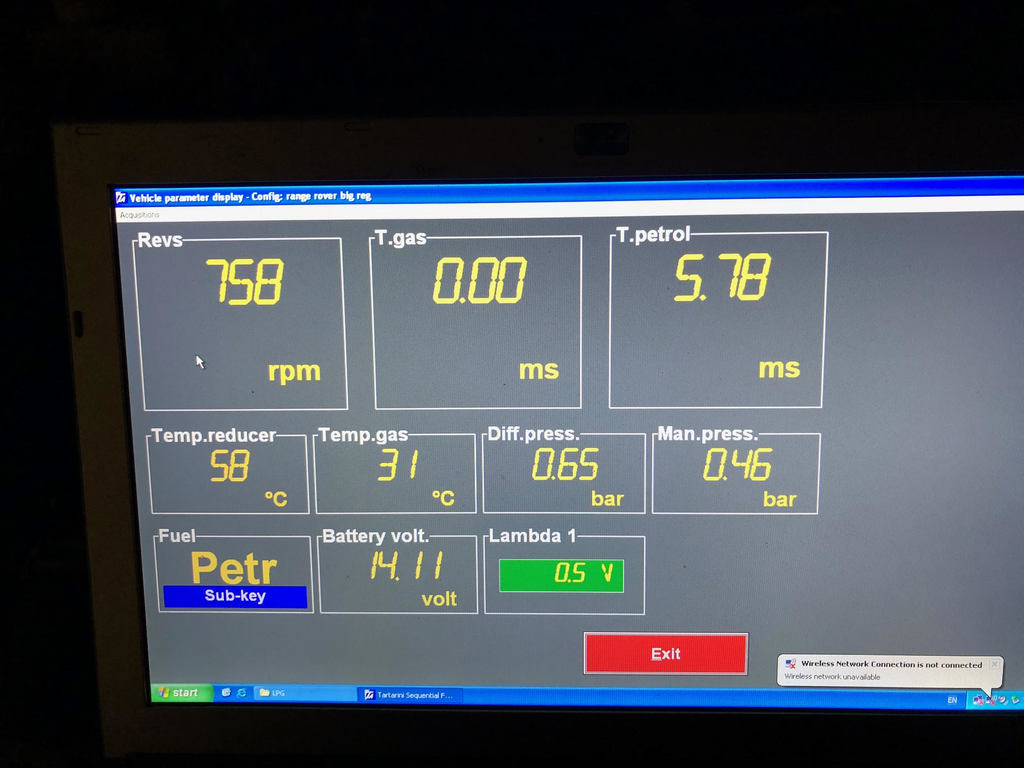

Starting the car on Petrol and observing the Diff. Press figures we had a reading of 0.65 bar.

Starting on Petrol:

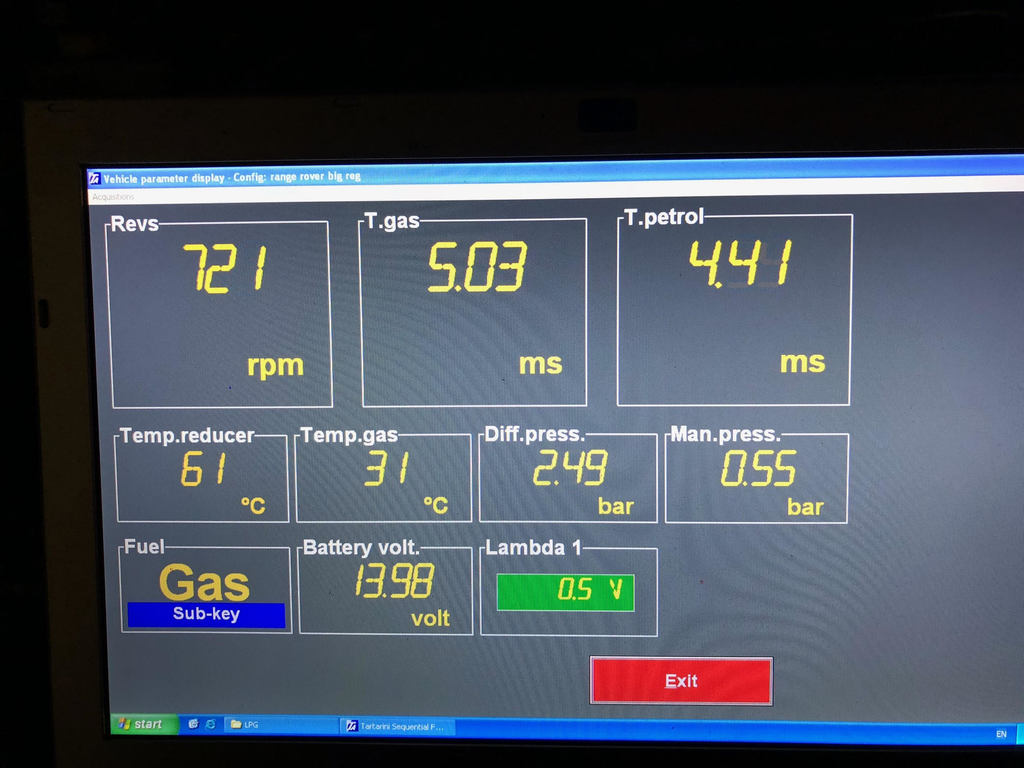

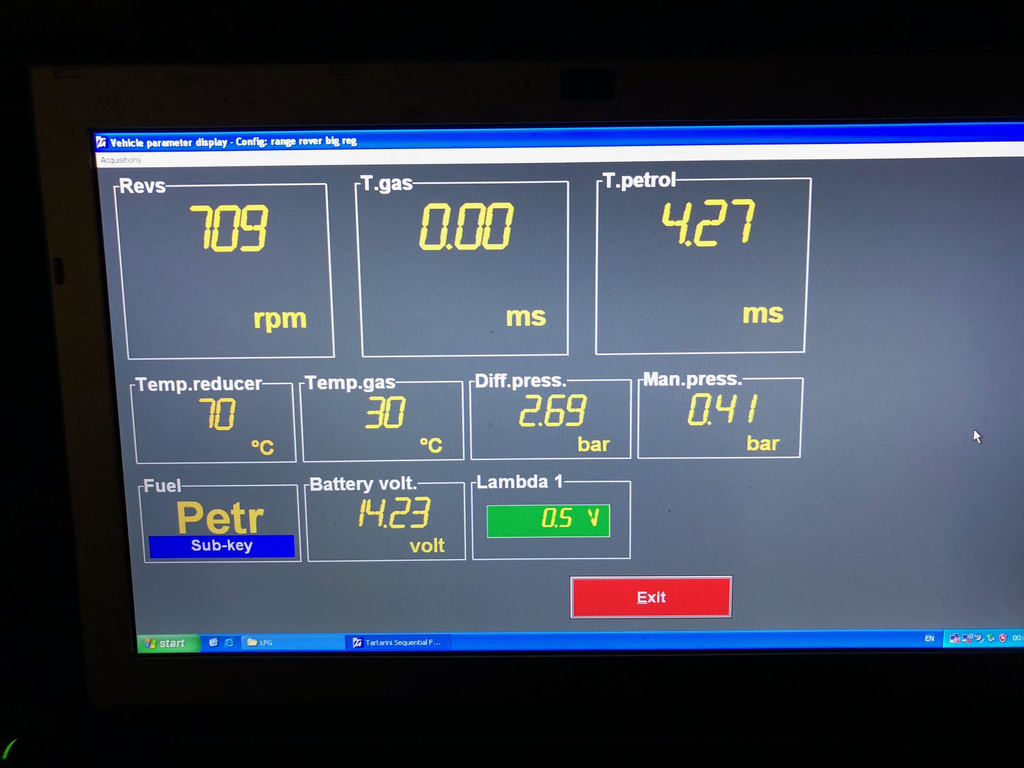

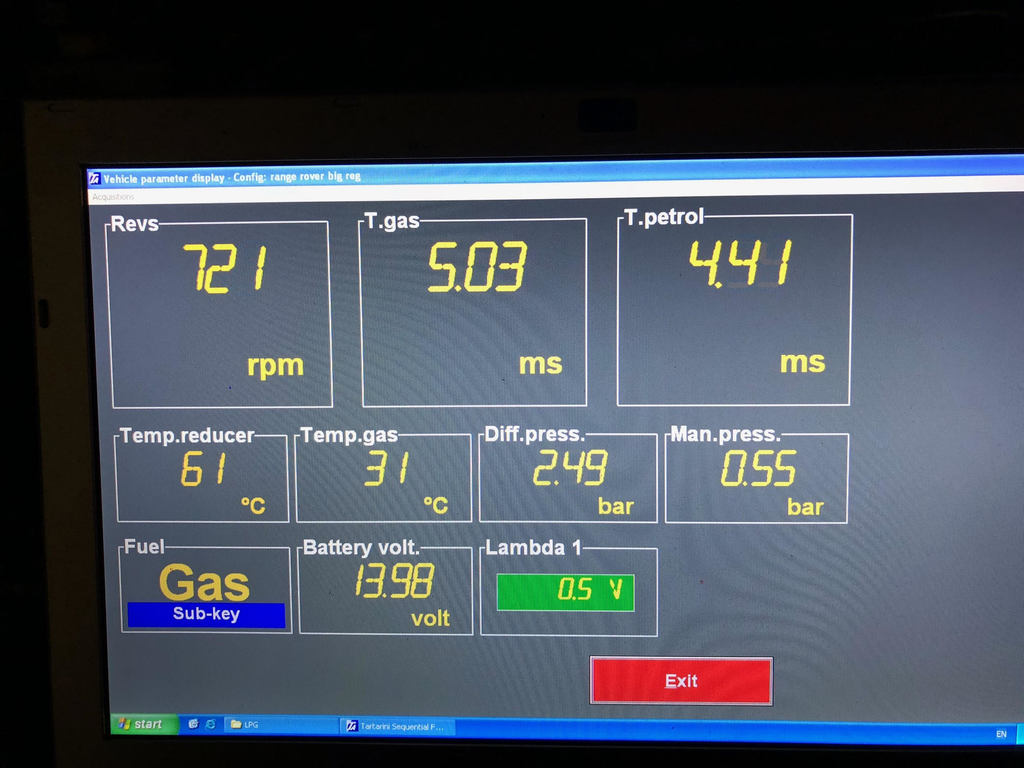

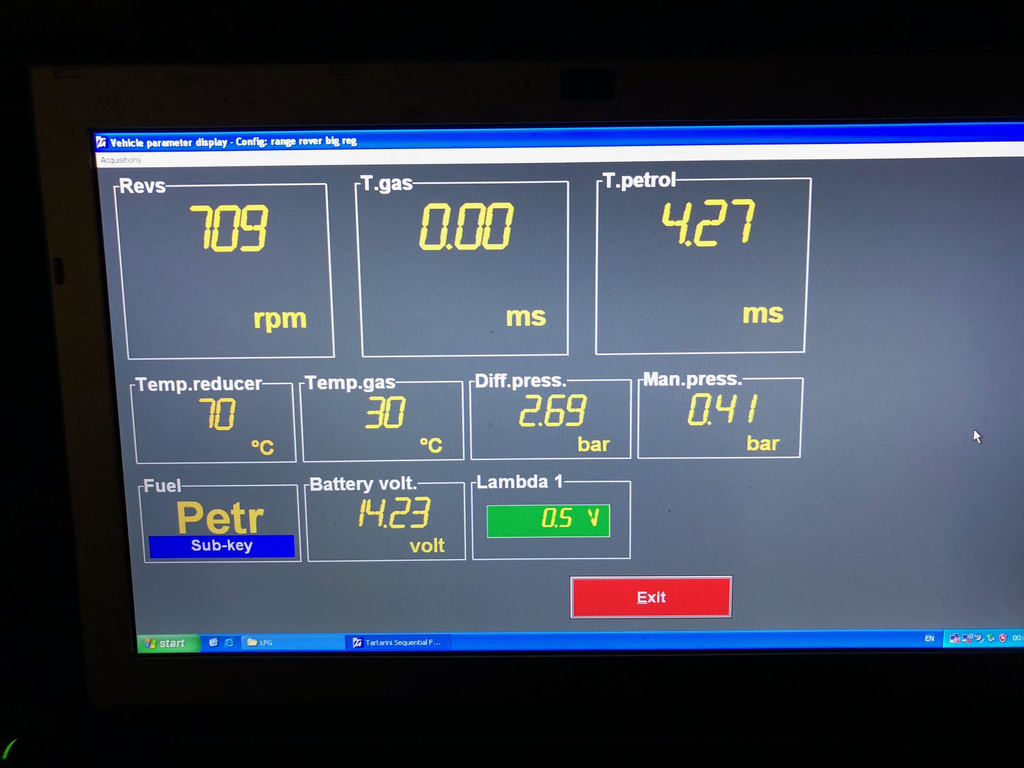

Switching the car to LPG changed the reading, it went straight to 2.49 bar, switching back to petrol from LPG left us with a reading of 2.69 bar.

Switched to LPG:

Switched back to Petrol:

Squeezing the thin rubber tube between the reducer and the pressure switch didn't seem to make any difference to the reading regardless of how hard it was squeezed.

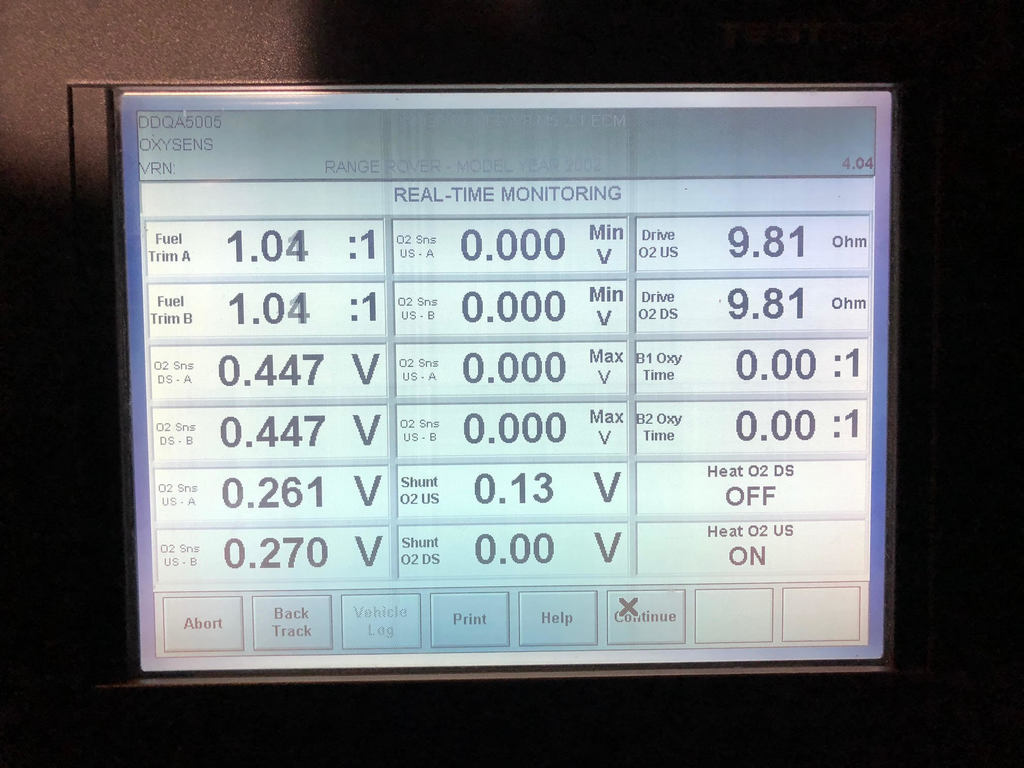

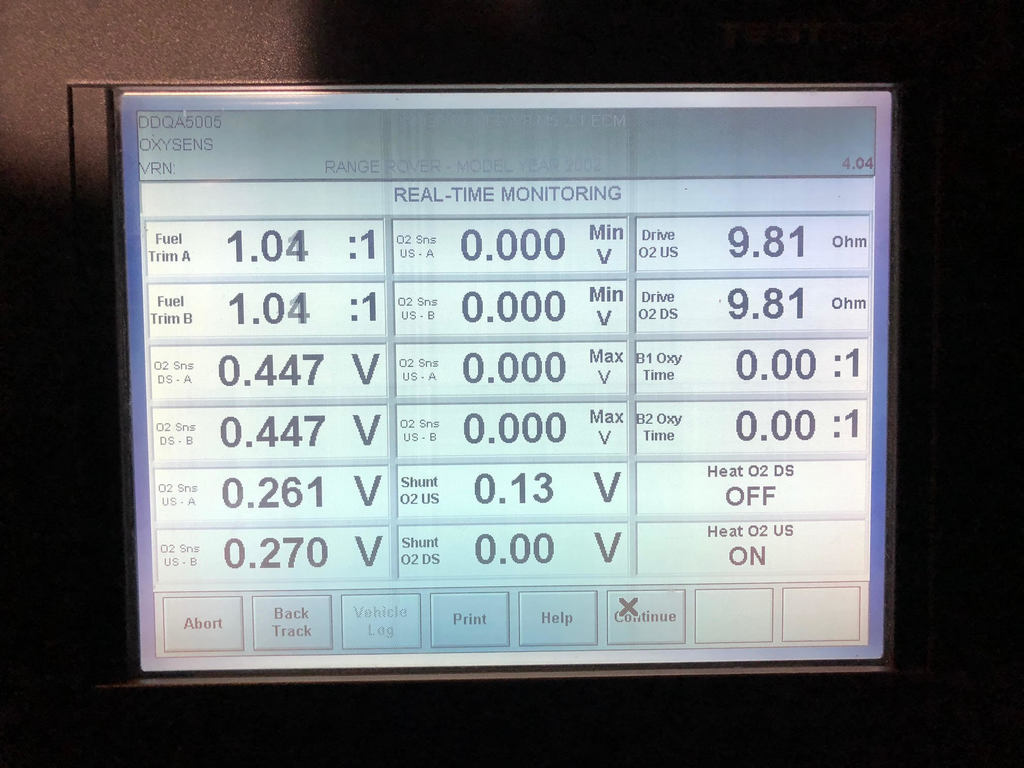

When we waved Testbook at it earlier on I noticed there's a fault logged with both Upstream Lambda sensors now which there wasn't last week. Testbook shows a reading for 4 lambda sensors yet there's only 2 in the exhaust. That surprised me as my old 2000 Discovery V8 definitely had 4 sensors... Has someone removed mine and blanked them off or do the P38's only have 2 sensors?

Readings from Testbook were:

O2 Sns DS - A - 0.447v

O2 Sns DS - B - 0.447v

O2 Sns US - A - 0.261v

O2 Sns US - B - 0.270v

Both of the Upstream sensors were observed switching like you'd expect, I noticed that the DS heater stayed permanently off and the US heater was switching on and off too.

Testbook Readings:

I'll get a few more miles on it and if the fault codes for the lambda sensors comes back again I'll replace them both.

The fuel trims look nice and even on petrol though which is good.

1995 4.6 HSE - Biarritz Blue - Breaker

2002 4.6 Vogue SE - Alveston Red

2007 4.2 Supercharged - Java Black

2012 4.4 TDV8 Autobiography - Baltic Blue