The saga continues . . .

Rangie has performed flawlessly since the last drama - no apparent power drain, Hankook battery back to rude health, firing up 'on the button', EAS compressor operating happily . . . until yesterday evening! Unlocked OK on the fob, ignition on with no usual signs of low voltage, twisted the key to fire her up and . . . nothing - and I mean nothing, not even the faintest of clicks . . . arghh!

This morning the investigation began - battery voltage absolutely fine, fuse 40 not blown, power at the starter relay, starter motor relay bench tested OK. Jumped the relay and . . . nothing! Need to get at the starter motor to complete checks but she's down at access level and parked such that getting a jack in under the axle is difficult to say the least. No problem, Nanocom will provide control to heave the beast up to high level so I can squeeze under. Nano connected, ignition on, select EAS and then hit High level and a message pops up stating that the engine needs to be running and doors closed . . . double arghh! But wait, Nano lies - hit the OK button under the message and up she goes - result!

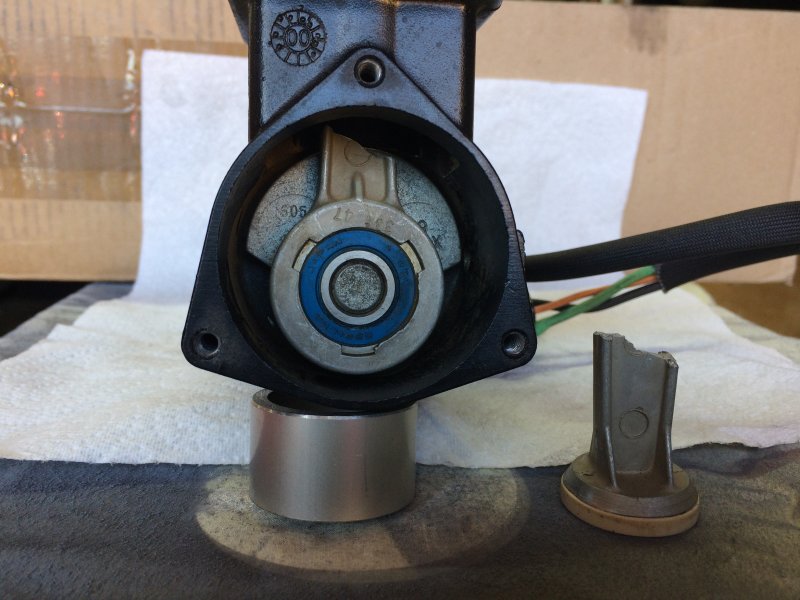

Squeeze under (a door left open of course) and check continuity of solenoid wire - OK. Check voltage with relay jumped - full 12V available at the terminal. Check earthing of starter motor - OK. Get trusty mallet and give the solenoid a good beating and voila - starter spins happily!

The previous drama seems to be just complete coincidence with the starter motor and compressor going AWOL at the same time and now who really is the culprit for blowing fuse 40 previously? I have withdrawn my previous apology to the starter motor and given the solenoid more whacks than necessary to vent my frustration!

Rebuild or replace? Does anyone do rebuild kits for these starter motors? Are the (very) cheap replacement 'aftermarket' starter motors any good or should I go OEM?

2001 Vogue

Yes . . . . . . I do own the road