Mrs Garvin had a folding hard top MkIII MX-5. Initially thought we would keep it for 3 years but ended up keeping it for 8 years as a) it was a lot of fun; and b) it proved to be the most reliable car we have ever owned by a country mile. In those 8 years and £44k miles it only required, apart from annual servicing, a set of front brake pads (discs were still only slightly worn), tyres and a new battery with the latter only required cos Mrs E left the boot ajar with the boot light on when we were away for a couple of weeks. The 7 year battery never recovered from that deep discharge!

Other good points:

- Great handling with not too much grip so fun to be had at sensible speeds. Very adjustable via the throttle.

- Lovely steering feel, you know exactly what’s going on with the front wheels.

- Slick, rifle bolt gear change

- Good driving position with great relationship of steering wheel and gear shift and nicely positioned and weighted pedals but see item 1 below.

- Boot capacity not bad and not reduced when the roof is folded.

- The only drop top I have ever driven that didn’t leak even when it was chucking it down.

Not so good points:

- Tight fit for 6 footers. I’m 6’1” and it was OK to drive for up to 30 mins. Long journeys a no-no. The foot well in the passenger side is far too small and a lot smaller than the driver’s side. I thought this odd and on investigation found a removable plastic wedge under the carpet. Once removed the seating position for anyone over 5’10” became OK but still not great.

- Lack of power. Only had ~125bhp and needed just a bit more oomph.

- Engine revved well but was a bit noisy/coarse.

- Cost of spark plugs - when they were changed at service I initially thought they had made a mistake on the invoice but Googling them revealed the OEM ones were over £20 each, yes that’s right, over £80 for four of the damn things and that was back in 2012 or so.

- OEM ICE was pants. Was changed PDQ.

Would we have another one? Well, by coincidence we have a latest version on order that should be with us at end October. I tried one out for size and I fit in it a lot better than the MkIII and an extra 60 or so horses should make things more fun - after years of high powered cars that were just too fast for UK roads I fancied having something I could actually ring the neck of again and slide around.

The top corner is a weak spot, I’ve had a couple go there. There seems to some weird interaction with moisture and abrasion at that point, probably to do with airflow. The last one I had fitted I taped around that corner and then cut a piece of soft foam for the corner and then taped that on. Haven’t had any trouble since.

Additional exhaust hangers arrived so the very two rear most ones have been replaced as have the four bump stops. Rear axle pinion flange seal was weeping so replaced that as well. The back end had seemed a little bouncy of late, certainly some skipping when cornering on broken surfaces so the 22 year old dampers were replaced all round. Oil and filter change plus new spark plugs finished the latest round of maintenance.

Removing/replacing the battery cover is hardly a chore - it has just three quick release fasteners. However, having said that I have fitted one of these which does make battery charging a lot easier:

Whilst on this thread I have also been busy fixing an annoying leak from the front diff pinion flange - spangly new flange, seal and nuts/bolts fitted:

July is annual service time but before embarking on the usual oil and filter changes I have just fitted a new NSR mudflap (with bigger, meatier fasteners), replaced a very tired looking exhaust rubber mounting and had the slide pins out of all the brake calipers to be cleaned and regreased. Couple of other exhaust hangers to be replaced (when the replacements arrive) and all four bump stops (which I have) to be replaced.

I refurbished the subwoofer a couple of years ago - the cones had disintegrated, a common problem I put down to the speakers not being man enough to cope with the movement required of a subwoofer. I thought I'd try some more 'meatier' 6.5" speakers and went for Lanzar MaxP64 Max Pro - pretty cheap and looked robust. Probably not best matched to the amp but are performing pretty well and can take the bass being wound up a lot more than the OEMs.

The Lanzar speakers do not quite fit into the subwoofer box cut outs at the top as the substantial top rings are a bit too wide (a mm or so). Two options - remove the substantial rings or ease out the cut outs. I went for the latter as the former would leave the cones not that well fixed/supported so would probably disintegrate as per the OEMs. The trusty dremel made opening up the cut outs quite easy. The Lanzars also need longer screws as the OEM fasterners were a bit too short with the thicker top rings.

I also moved the amp to the bottom of the subwoofer box but did not employ such an elegant solution as Chasman. The amp was bolted directly to the bottom of the OEM speakers so I figured vibration couldn't be that much of a problem. I fashioned an off cut of wood to fit around the rib and screwed this to the bottom of the box and then screwed the amp directly to its new wooden support. The wires twixt amp and speaker had to be extended to reach between the two.

All pretty simple/easy modifications. Piccy:

I also bought a couple of new cones for the OEM speakers and refurbished them - they are now sat in my growing stash of 'ready use' spares!

Yes, I was looking at the Transmax - I also notice on that site that a single 5 litre bottle is more expensive than 5 x 1 litre bottles!!!

Time to refresh the fluids in the automatic gearbox, transfer box and power steering. As Dexron III is the specified ATF for all these does anyone have a recommendation for a suitable product (or ones to avoid)?

Over speed warning. Rarely am I given to RTFM but I did . . . and there it is, a spectacularly useless option I never knew I needed or even existed . . . and I’ve had this P38 for nearly 19 years! Now I’m tempted to see if mine works, but not if the annoying thing can’t be switched off!

Today I completed the refurbishment of the errant starter motor. A few piccies:

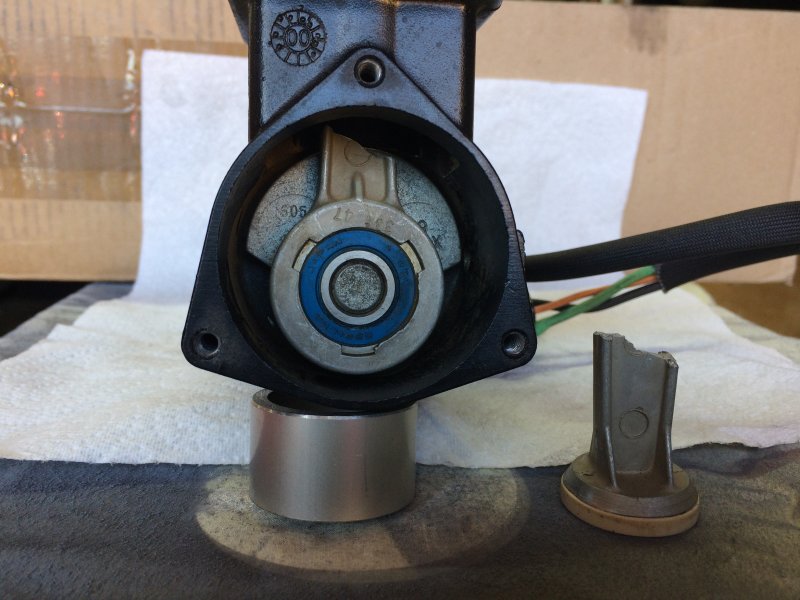

First stage of disassembly - note the orange shroud around the solenoid piston. Not seen one of these before but I assume it’s there to keep the solenoid inner workings as clean as possible:

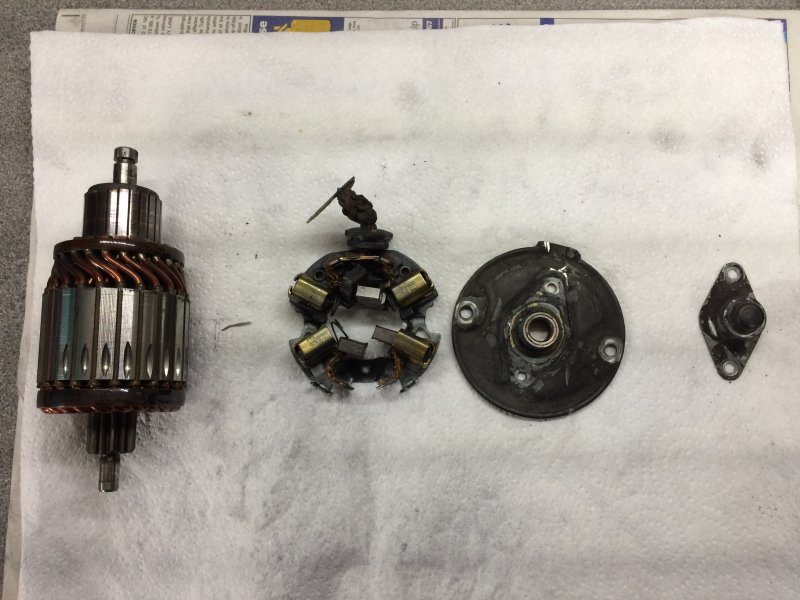

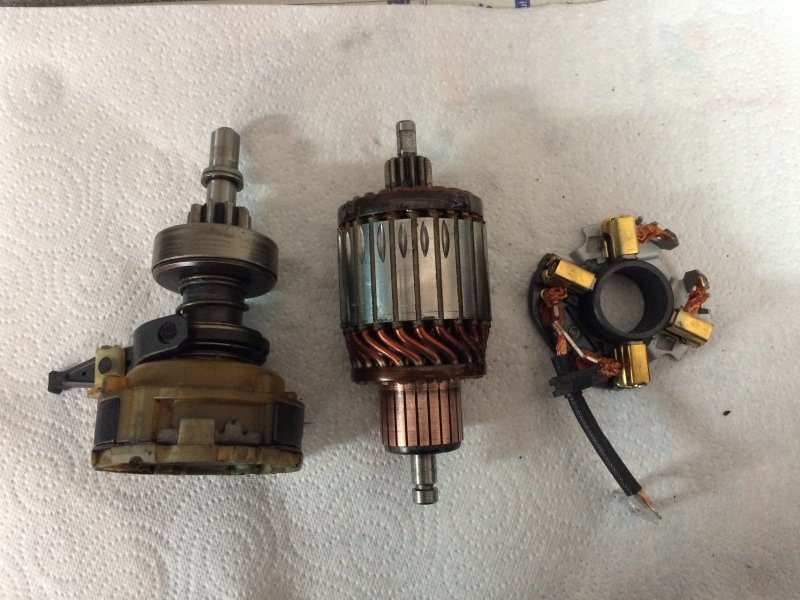

Second stage of disassembly - the main motor components:

Third sage of disassembly - the solenoid. I feared this may be the problem child but couldn’t find any clear problem. The piston seemed pretty clean and moved freely. All the contacts conned out OK but were thoroughly cleaned as were its inner workings:

Items after a run in the wash tank and the blast cabinet to remove paint and generally clean them up ready for painting:

Main motor bits cleaned up, commutator and bush/bearing surfaces polished. All gears were cleaned out and re-greased. The new brush cage assembly is also in shot:

Parts masked up and then painted in primer ready for top coat:

Once the top coat had dried all items were then inspected, thoroughly cleaned (again) ready for reassembly. I did not find any real problem, even the carbon brushes and cage assembly looked to have plenty of life left - it was renewed anyway. The whole unit was then reassembled. The biggest problem experienced during this exercise was disassembly and getting the fixings out. The main through bolts were OK but the three bolts holding the solenoid in place and the two small screws locating the brush cage in place were a right pain. The heads seemed to be made of chocolate and chewed up rather quickly and easily rather than just unscrew. Perseverance beat them into submission and new Allen head stainless steel bolts replaced them.

The acid test was a few test runs on the bench. Here’s a video of one:

It’s now packaged up and on the shelf joining my other ready use spares!

The motor turns quite easily and the 'big end' bearing is not seized or tight - rotates quite easily. The cylinder bore has some wear but nothing more than one would expect for 3 years running (when it was last refurbished). The piston and seal are both undamaged and, again, no abnormal wear on either of them. I can only put this down to a weak con rod and one refurbishment too many - although the break looks very clean with no obvious sign of fatigue! I don't suppose the design life for the compressor was for 20 years+!

New starter motor installed and working fine. Old starter motor currently undergoing refurbishment. Whilst waiting for the paint to dry on the casing bits and pieces before final reassembly I thought I would see if the EAS Compressor that appeared to overheat and seize could be resurrected and refurbished so I started disassembly and discovered the reason for the 'seizure' - can anybody spot what could possibly be the problem?

Removing the front bumper is quicker and easier than removing the fog light - the upper two locating screws on the fog light take some getting at and, if rusted, will prove difficult and time consuming. Two bolts, two clips (reach up inside the wheel arch liner and flick them up), two fog light connectors and vent tubes and off she slides which gives full access to the pumps, the washer tubes and the wiring/connectors.. No need to drain the reservoir, just a swift dexterous swap of the pump (push fit) and tube with minimal fluid loss but you will get your sleeves wet so roll ‘em up. You can also catch most of the ‘leaked’ fluid for reuse with a handily placed bowl of some sort. Connector swap is then also simple. Liberally grease the bumper clips and their plastic locating pads inside the bumper, plenty of anti seize on the bumper bolts when refitting and you’re well prepared for the next time.

The whole process takes less than 15 minutes.

Following the saga of the dying starter motor (separate thread) a new starter was fitted. For a large vehicle with what should be plenty of room it’s a bit of a pig to do. Coupled with the ‘meaty’ Hankook battery it surprised me just how quick it spun the V8. Next job is to refurbish the old starter motor.

As removing the wheel arch liner would facilitate the removal/replacement of the starter motor I took the opportunity to replace the rather sad looking OSF mud flap. As expected, the mud flap fixings were completely corroded so all were cut/ground off to remove the old mud flap, the new one being replaced with uprated fasteners all round cos bigger is always better!

Whilst under the wheel arch the brakes discs and pads were thoroughly checked - all OK and I also took the opportunity to remove the caliper sliding pins and clean/re-grease them.

Check the ARB bushes and drop links first. Much easier to check and sort out before getting serious with ball joints!

After hours of research it appears that there are cheap solenoids on the market . . . but none in stock - story of my life recently! However, having now further researched the solenoid it appears a pretty simple assembly that probably just needs a thorough clean/greasing and my trusty dremel might be able to sort out any errant contacts with a bit of grinding and polishing - we'll see! I have also found a carbon brush assembly for £22.90 delivered so with that ordered refurbishment of existing Starter is now on the cards. This means I will just select a cheap and cheerful replacement starter for immediate use and keep the refurbished one on the shelf alongside my other 'ready use' spares in case the cheap replacement doesn't prove so cheerful!

The main motor seems fine, it’s the solenoid that needs ‘fettling’ which usually means, as well as a general clean up, pitted contacts that need replacing but I can’t find replacements anywhere - seems to be the whole solenoid assembly at vast cost . . . or nothing. That’s not to say I wouldn’t renew the brushes in the main motor but I can only find the complete brush ‘cage’ assembly rather than just the brushes. When these two parts are added together the cost makes refurbishment non cost effective.

I am quite OK ‘refurbishing’ starter motors (have done a number in my time - the last one was done in June last year!) but it’s nice to know what brushes and contacts to get so if anyone knows please post up the information. The starter seems to be a ‘generic’ unit used on a number of vehicles so the info must be out there somewhere . . . but where?

If I can get hold of the necessary bits and pieces I’ll get a cheap replacement whilst I refurbish the original, otherwise I’ll go OEM.

The saga continues . . .

Rangie has performed flawlessly since the last drama - no apparent power drain, Hankook battery back to rude health, firing up 'on the button', EAS compressor operating happily . . . until yesterday evening! Unlocked OK on the fob, ignition on with no usual signs of low voltage, twisted the key to fire her up and . . . nothing - and I mean nothing, not even the faintest of clicks . . . arghh!

This morning the investigation began - battery voltage absolutely fine, fuse 40 not blown, power at the starter relay, starter motor relay bench tested OK. Jumped the relay and . . . nothing! Need to get at the starter motor to complete checks but she's down at access level and parked such that getting a jack in under the axle is difficult to say the least. No problem, Nanocom will provide control to heave the beast up to high level so I can squeeze under. Nano connected, ignition on, select EAS and then hit High level and a message pops up stating that the engine needs to be running and doors closed . . . double arghh! But wait, Nano lies - hit the OK button under the message and up she goes - result!

Squeeze under (a door left open of course) and check continuity of solenoid wire - OK. Check voltage with relay jumped - full 12V available at the terminal. Check earthing of starter motor - OK. Get trusty mallet and give the solenoid a good beating and voila - starter spins happily!

The previous drama seems to be just complete coincidence with the starter motor and compressor going AWOL at the same time and now who really is the culprit for blowing fuse 40 previously? I have withdrawn my previous apology to the starter motor and given the solenoid more whacks than necessary to vent my frustration!

Rebuild or replace? Does anyone do rebuild kits for these starter motors? Are the (very) cheap replacement 'aftermarket' starter motors any good or should I go OEM?

LEDs last much longer? Supposed to but if the problems I've had with domestic LEDs is anything to go by then I wouldn't bank on it - seems that the requirement for much more connections within the LED array is a particularly weak point - plenty of U-Tube videos now available on how to 'fix' those expensive LED bulbs that, apparently, will outlive you! Indeed, fix is the wrong word as they just short circuit the errant LED out of the matrix.

Besides which, Rangie is 22 years old and I've only had to replace a couple of bulbs that have failed and not, as far as I can remember, a dash bulb! Compared to the rest of the things that need regularly replacing because they fail the bulbs are way, way down the list!

Having said that a LED set up for the luggage compartment is definitely a good idea.

I have LEDs fitted to front sidelights only with no problem as I use these as the increased light intensity in low light conditions not warranting headlights seems worthwhile to be seen. I do not have them fitted to any other lights but am led (pun intended) to believe that careful selection of LED lamps designed to work with the P38 operate without problem but cannot confirm this personally.

I have uprated halogens fitted to the head and driving lamps as the stock system is pretty damn good and the lower blue light and higher yellow light content mean they are much better during misty/foggy conditions. As for the rear lights, the stock system of halogens is more than adequate for rear, brake and turn signal and higher intensity would just irritate following drivers for no good reason.. However I am tempted to fit LEDs to the reversing lamps as the higher intensity/lumens would aid vision when reversing in the dark.