Another vote for General Grabbers here. I've got AT2 on my Jeep (40,000 miles so far) and AT on the P38. I've offroaded the jeep at a pay and play site and was amazed how well it went. The P38 has only done muddy tracks and wet grass, but it coped very well. Both tyres have good road manners and do well in the snow.

General are Continental's SUV/4x4 division.

It could be a diff, my front let go with a pop then a worryingly loud regular clunk/growl depending on road speed after a tooth broke off the CWP. We drove it home (150 miles) but it clearly wasn't happy.

Does the noise it is making now sound similar to your broken diff (what was wrong with your old diff?)

Was the new front diff set up properly by the garage? Mine broke because it was a recent replacement that had incorrect backlash set on the crownwheel pinion which lead to premature failure. It might be worth popping the front diff cover off to have a look for obvious damage/bits of loose metal. Ashrcroft can have a replacement to you in 24hrs.

Or you could just smuggle them in, hidden in a container full of cocaine?

The titanic has landed. Or been raised, or whatever. One actually looks pretty good. I guess the other two are serviceable with new O rings.

I can't help thinking that I really should have bought a 3D printer when I had the chance...

I thought that was Thailand?

Don't, I've still got a full gasket set and new headbolts for an E30 325i along with two sets of alloys (summer and winter tyres).

Trouble is there are so few E30s on the market now that are worth looking at the parts are actually pretty worthless!

Thanks for looking :)

TBH, I've already paid for the whole block from Mr Titanic so I guess I'll see what arrives before I abuse BPSM's good nature again...

Yeah, but I'm not the guy who refurbed it last time :P

Chris, there's there's LOADS of O rings! I've paused while I wait for new NRVs so I've ordered some rinky dink silicon O-Ring lube to use on them. It's fun searching for O Ring lube, even on ebay :D

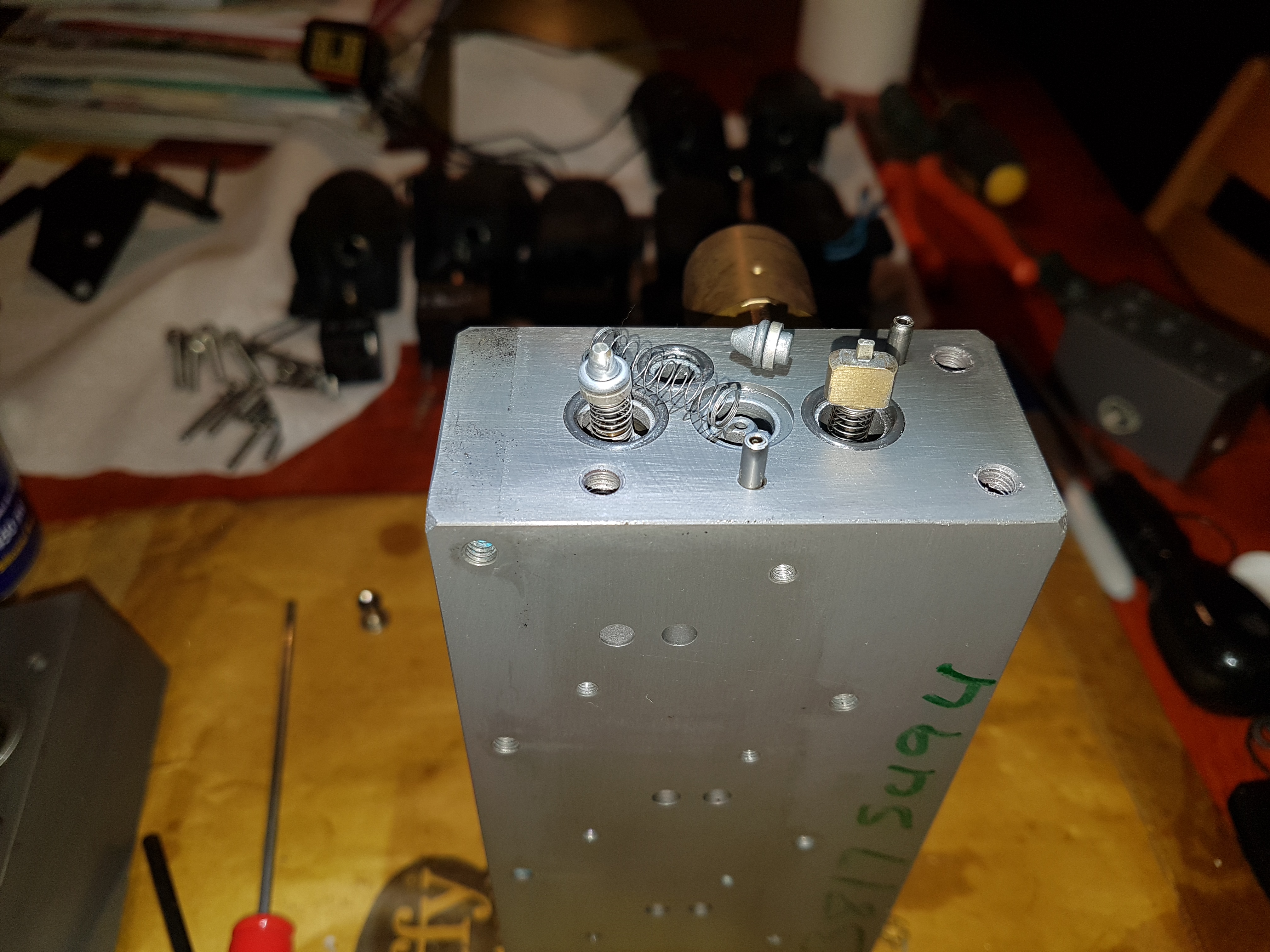

Yes, I think they had all been lubed. There was a lot of grey slimey grease in the holes and the NRV that was stuck was able to hold a puddle of WD40 back for about 20 seconds.

And after a couple of hours soaking in WD40 and a really good tug, it came out. I can't imagine that was helping the air flow either.

So, one NRV welded shut, one NRV basically free floating without a spindle. One collet was missing an O ring, the Diapragm and spring were rusty as hell.

All the O rings were lovely and new! I suspect the previous owner was a bit special. He certainly had a love of blue locktite.

Haha, all donations gratefully received :)

btw, is the "backwards" NRV meant to come out? The one with the cone facing inside the block. Mine seems to be stuck. I could grab it with pliers but I don't want to rip it out unless it's mean to shift.

Orangebean wrote:

Me?

Don't remember any valves- emergency or otherwise!

No, me :) I'm the one with a load of other people's P38 parts!

BPSM, could you PM me your address? If you sent it, I've lost it :(

Also, if you don't mind telling me where you got this set would it be OK if I just bought a new set and had them shipped to you direct? It would save a bit of postage (which I could pass on as I owe you for the last lot).

Heh :)

anyway, fuggit. I need this fixed before a certain 6 year old spreads all the parts over the floor where they will be eaten by ravenous Basset Hounds

I hope there's at least one decent NRV in this

https://www.ebay.co.uk/itm/302440386308

So, I guess that wasn't working very well :(

Houston, we have a problem :(

ROFL, cold :)

It has begun! I'm using this guide: http://paulp38a.com/range-rover-p38/eas-valve-block-renew/

Just quick question though, Should the solenoid covers all have square rubber gaskets/grommets to seal them? only one of mine did.

So far it has all looked in perfect nick with no sign of swarf from the dead compressor. The only horrible bit so far was this:

Btw Marty, now we've had some snow the heater matrix and heated seats are much appreciated thank you 😀

🎯👌

Sadly I now need the same in my jeep which has no heat at all now. Gotta laugh! Luckily there is a garage a lot closer than Swindon so I won't be risking frostbite on another 5 hour winter drive 😁

Orangebean wrote:

Morat wrote:

I think it's good practice to bung it into low range every few weeks just to keep everything free and working. Or maybe that's my personal justification for fiddling with all the buttons :)

The only thing I can't do is get the High Range into 1 reliably.

Stop fiddling with the buttons and get your valve block rebuilt :)

There's adjustment on the selector cable where it connects to the operating arm on the box. Might just need a bit of a tweak.

It's a great team building exercise for yourself and Mrs Morat. She gets to sit in the car and exercise the gear lever. You get to lie underneath and adjust.

In the snow. Sod that ;)

Valve block. Yes. Will do!